In a major leap forward for display technology, researchers from Zhejiang University have unveiled the world’s smallest LED pixel — measuring just 90 nanometers (nm) — setting a new benchmark in resolution and efficiency for next-generation displays.

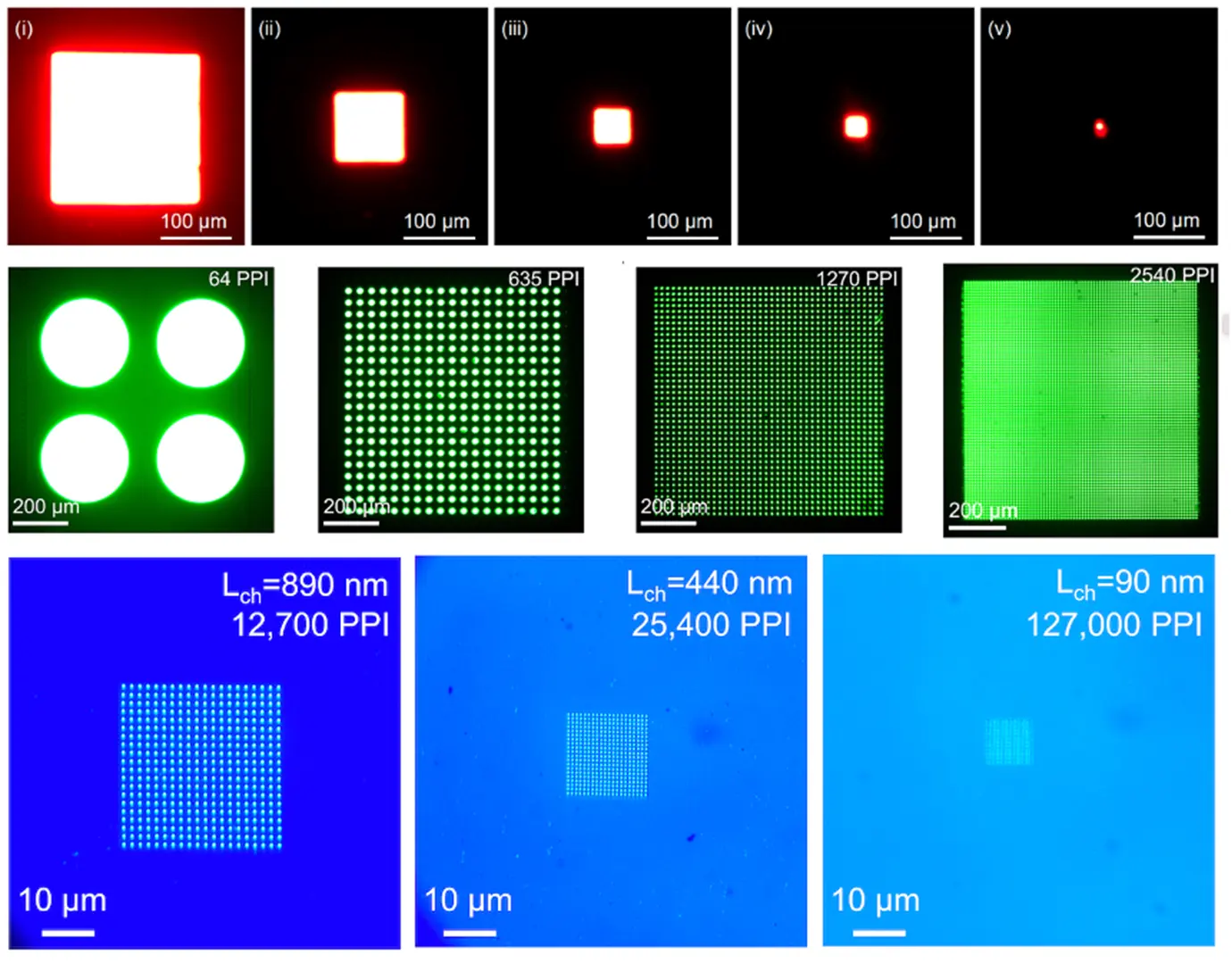

Led by Professor David Di and Professor Baodan Zhao, the research team published their findings in Nature under the title "Downscaling micro- and nano-perovskite LEDs." Their work introduces an ultra-high-resolution LED array capable of achieving 127,000 pixels per inch (PPI) — the highest resolution ever recorded in LED display technology.

Traditional III-V semiconductor-based Micro LED displays face significant limitations:

High manufacturing costs

Sharp efficiency drop when scaled below ~10 microns

The new solution? Perovskite LEDs (PeLEDs), which offer several key advantages:

Lower production costs

Excellent performance at nanoscale dimensions

External quantum efficiencies (EQE) of 20–30%, comparable to OLEDs

Longer operational lifetimes approaching OLED standards

This innovation opens the door to high-performance, cost-effective displays that were previously unattainable with conventional Micro LED technology.

At the heart of this achievement is a novel fabrication technique known as the localized contact process. The method uses an insulating layer with patterned windows to prevent direct exposure of perovskite materials to electrodes, significantly reducing non-radiative energy loss.

As a result, PeLEDs maintain high efficiency even at ultra-small sizes — a critical milestone for future high-resolution applications.

| Parameter | Perovskite LED (PeLED) | III-V Micro LED |

|---|---|---|

| Smallest Pixel Size | 90 nm | ~10 µm (10,000 nm) |

| Efficiency Drop | Starts at ~180 nm | Below 10 µm |

| PPI Achieved | 127,000 PPI | ~5,000 PPI (commercial) |

| Manufacturing Cost | Low (solution-processable) | High (epitaxy & mass transfer required) |

PeLEDs clearly outperform traditional Micro LEDs in both scalability and efficiency at smaller scales, making them ideal candidates for next-gen visual technologies.

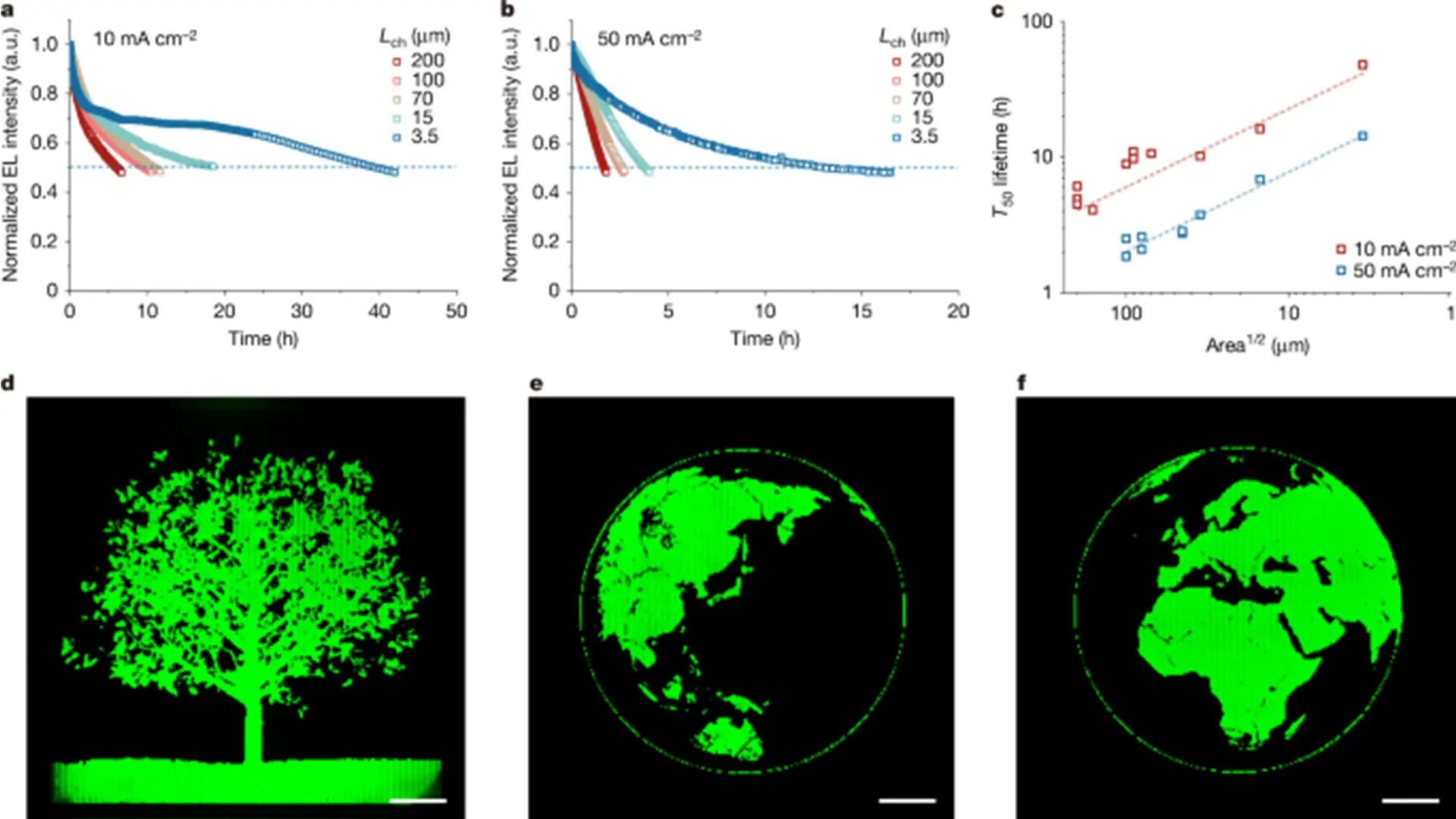

The team also demonstrated a working prototype of an active-matrix micro-PeLED display using commercial thin-film transistor (TFT) backplanes — proving its viability for practical, high-resolution applications.

Potential use cases include:

Augmented Reality (AR) and Virtual Reality (VR) – Retina-level clarity with ultra-high PPI

Wearable Displays – Lightweight and power-efficient

Smart Glasses & Head-Up Displays (HUDs) – High brightness with low power consumption

Despite this breakthrough, several challenges remain before PeLEDs reach mass production:

Lifetime and Stability: While current PeLEDs approach OLED-like lifespans, further improvements are needed for commercial deployment.

Scalability: Transitioning from lab-scale prototypes to large-volume manufacturing will require innovations like inkjet printing and roll-to-roll processing.

Competition: Micro OLED and quantum dot-enhanced Micro LED technologies are also advancing rapidly.

However, the unprecedented pixel density of PeLEDs gives them a unique edge in niche, high-resolution markets.

Driven by demand for ultra-high-resolution displays and advancements in hybrid LED technologies, the global thin-film Micro LED market is poised for strong growth. Key sectors fueling this expansion include:

AR/VR headsets

Automotive HUDs

Smart wearables

According to recent industry analysis, these trends will accelerate investment and R&D in perovskite and related display technologies.

The development of a 90nm PeLED pixel marks a turning point in the evolution of display technology. With:

Unprecedented pixel density (127,000 PPI)

Lower manufacturing costs compared to III-V Micro LEDs

Sustained efficiency at nanoscale sizes

Perovskite-based Micro LED displays are well-positioned to lead the next wave of innovation — especially in AR/VR, wearable devices, and other high-end visual applications.

As research continues and production techniques mature, PeLEDs could soon become the standard for ultra-high-definition displays across industries.

Hot Recommendations

Hot Products

Get a Free Quote Instantly!

Talk to Our Sales Team Now.

If you are interested in our products, please contact us promptly

Reach out to our sales team to explore customized solutions that perfectly meet your business needs and address any questions you may have.

Email Address:info@reissopto.comFactory Address:Building 6, Huike Flat Panel Display Industrial Park, No. 1, Gongye 2nd Road, Shiyan Shilong Community, Bao'an District, Shenzhen city , China

whatsapp:+8615217757270