The rise of high-resolution visual communication has positioned COB LED Display as a leading technology in the modern display industry. Offering superior image quality, enhanced durability, and seamless integration into various environments, COB (Chip-on-Board) LED displays are redefining what’s possible with small pitch LED systems.

This article explores the fundamentals of COB LED Display technology, compares it to traditional COB vs SMD methods, and examines how innovations like the P0.4 LED Screen and Micro LED vs COB are shaping the future of Ultra HD Display solutions.

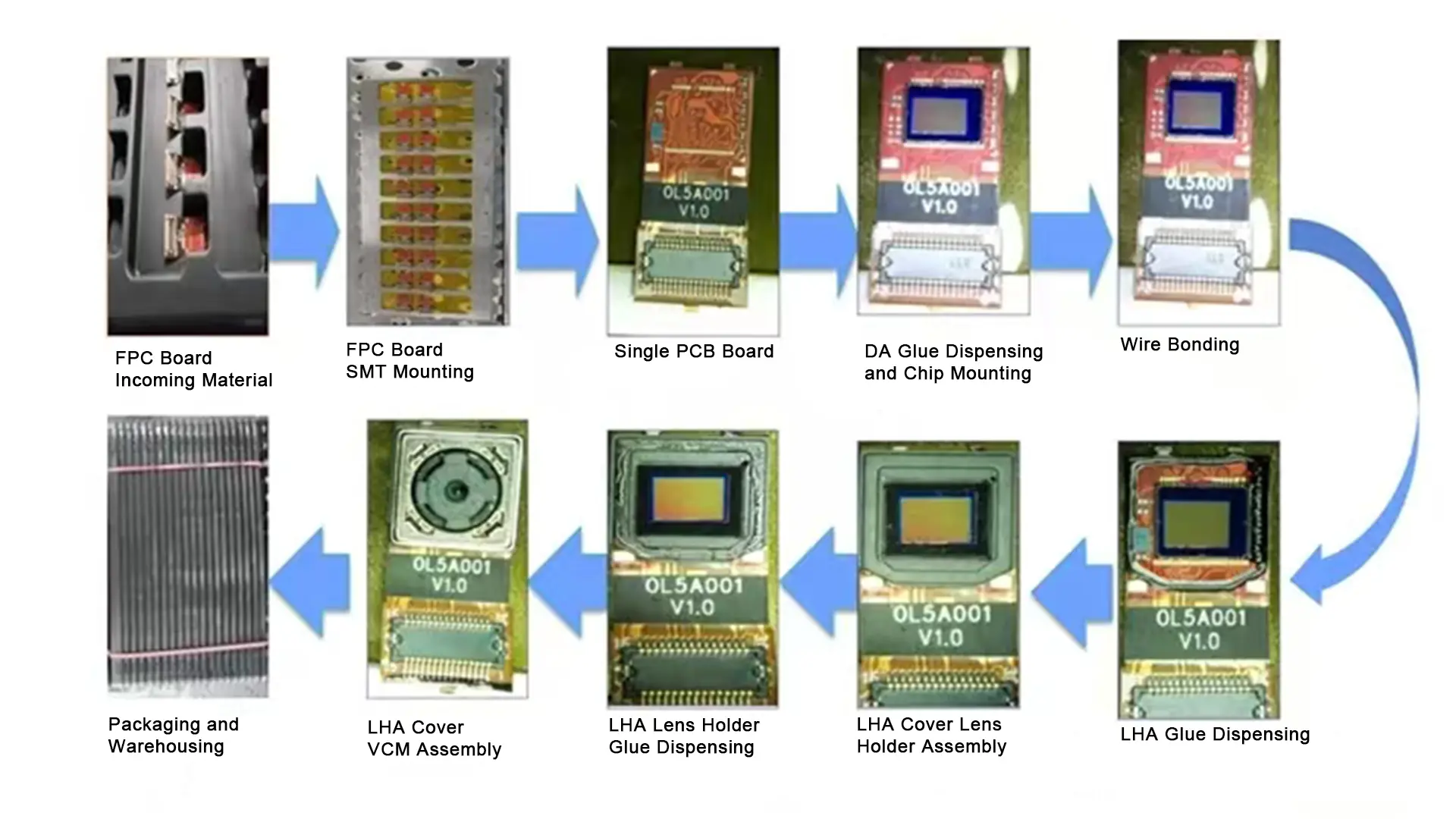

COB LED Display refers to an advanced packaging method where bare LED chips are directly mounted onto a printed circuit board (PCB). Unlike conventional Surface-Mounted Device (SMD) LEDs, which involve pre-packaging individual LEDs before mounting, COB eliminates this step by integrating multiple LED dies on a single substrate.

This approach significantly reduces the risk of component failure and allows for much finer pixel pitches—making it ideal for applications requiring ultra HD display performance and seamless LED video wall installations.

No Individual Lamp Bezel: Eliminates visible gaps between LEDs, enabling smoother visuals.

Better Thermal Management: Direct bonding to metal-core PCBs improves heat dissipation.

Enhanced Protection: Encapsulated resin coating provides dust and moisture resistance (IP54+).

| Aspect | COB LED | SMD LED |

|---|---|---|

| Chip Mounting | Directly bonded to PCB | Pre-packaged before mounting |

| Pixel Pitch | As low as P0.4 | Limited to ~P0.7 |

| Repairability | Difficult to repair individual LEDs | Easier to replace faulty units |

| Cost | Higher upfront cost | Lower cost but more maintenance |

While SMD remains popular for large-format outdoor displays due to lower costs and easier repair, COB LED Display excels in indoor, high-density applications such as control rooms, corporate lobbies, and digital signage where high reliability LED performance is critical.

The demand for small pitch LED screens has surged with the growth of 4K/8K resolution requirements. COB technology enables manufacturers to achieve P0.4 LED Screen resolutions, offering crystal-clear visuals at close viewing distances.

Its smooth surface and absence of graininess make it ideal for seamless LED video wall installations in command centers, broadcast studios, and high-end retail environments.

Producing a COB LED Display requires highly precise die bonding (±15μm accuracy), wire bonding, and encapsulation processes. Any misalignment or defect can render an entire module unusable, especially in modules with thousands of LEDs.

Due to the integrated nature of COB LED packaging, repairing a single LED is nearly impossible. This increases long-term maintenance costs compared to SMD displays, where individual components can be replaced.

The need for high-thermal-conductivity epoxy, cleanroom environments, and specialized manufacturing equipment contributes to higher production costs. However, these are offset by reduced field failures and longer lifespan (up to 100,000 hours).

One of the most promising developments in the display industry is the convergence of Micro LED vs COB technologies. By combining the structural benefits of COB with the self-emissive properties of Micro LED, manufacturers aim to create ultra-bright, ultra-thin, and ultra-reliable panels suitable for both consumer and professional markets.

Improved Yield Rates: Advances in automation and precision bonding will reduce production defects.

AI-Powered Calibration: Smart color correction and brightness balancing for consistent visuals across large installations.

Integration with IoT: Real-time monitoring of temperature, humidity, and performance metrics for predictive maintenance.

Wider Consumer Market Adoption: As costs decline, COB-based TVs and automotive displays may become mainstream.

The COB LED Display represents a major leap forward in LED Packaging Technology, setting new standards for high reliability LED performance, small pitch LED clarity, and ultra HD display fidelity. While challenges remain in manufacturing and repair, the benefits—especially in mission-critical environments—are undeniable.

As the industry moves toward hybrid technologies like Micro LED vs COB, we can expect even greater advancements in brightness, resolution, and energy efficiency. Whether it's for a seamless LED video wall in a control room or a next-generation home theater, COB LED technology is lighting the way into the future of visual communication.

Hot Recommendations

Hot Products

Get a Free Quote Instantly!

Talk to Our Sales Team Now.

If you are interested in our products, please contact us promptly

Reach out to our sales team to explore customized solutions that perfectly meet your business needs and address any questions you may have.

Email Address:info@reissopto.comFactory Address:Building 6, Huike Flat Panel Display Industrial Park, No. 1, Gongye 2nd Road, Shiyan Shilong Community, Bao'an District, Shenzhen city , China

whatsapp:+8615217757270